2021 is at its halfway point, demand for lumber has exploded and lumber prices have skyrocketed. Manufacturers and suppliers are playing catch up for industry pros to have the wood material they need. Not only are we all struggling to get lumber at the best price, but we’re also waiting 4-6 weeks or 2-3 months to receive it. For homeowners, designers, or contractors looking for organically beautiful, environmentally friendly, and affordable material – consider reconstituted veneer.

What is Reconstituted Veneer?

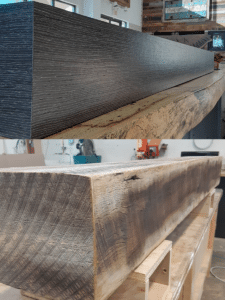

Reconstituted veneer is repurposed white hardwoods used to make stunning wood furniture and décor at a reasonable price. Recon veneer is thinly sliced from large, straight logs that have little to no defects. Logs are sustainably sourced and maximized by using the best part of the log for numerous sheets. With any kind of veneer, there is no worry about knots, insect damage, ring shake, or seams. Every single sheet has a similar color and grain, making it perfect for architectural panels. The unique appearance of the lumber is captured producing a stunning natural wood grain veneer.

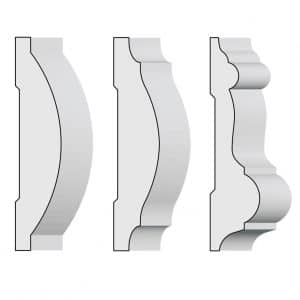

It is no secret that recomposed and man-made materials preserve natural resources needed for future generations. While reconstituted veneer is a valuable resource for green living, it does involve a lengthy process. First, the wood is sliced from the log then the sheets are dyed to get the desired wood grain color. Next, the thin strips of wood are layered, glued, and stained to replicate a beautiful, natural wood grain. The veneer block is pressed and re-sliced into paper-thin sheets that are used for countless projects. The block is turned for different cuts that produce different looks such as plain with cathedrals, rift, or quartered.

Why Reconstituted Veneer?

Not only are we helping preserve the environment by using reconstituted veneer but we’re also choosing a more durable material. When the veneer is placed onto MDF or substrate, it’s strengthening the thin sheet of wood and the finished product. Real wood moves – it can crack, warp or swell over time due to moist conditions or extreme temperatures. A reconstituted veneer can withstand those types of conditions and remain strong, unmoved for years to come.

Recon veneer is also ideal for large projects where the wood grain needs to be consistent throughout. Major commercial remodels utilize reconstituted veneer panels, cabinets, countertops, and more in a single space. This also makes it easy to match that specific color and grain if more material is needed later. Interior designers will choose recon veneer when their client wants an exotic wood species but doesn’t want to pay exotic prices.

At Woodstock Architectural Products, we supply a line of natural and Remarkable Veneers. Our real wood veneers come from across the globe spanning almost every single continent. They do not have a backer and are typically 4’x8’ sheets. We have a full gallery of different colors and species to choose from. If there is a veneer outside of our gallery, we can get it for you!