Share

One of the most important architectural details in your home is moulding. It is the frame to your entire house that sets the stage from ceiling to floor. Interior trim is versatile, beyond framing each room you can use decorative mouldings to add design accents to the walls. As the #1 provider of custom moulding profiles in Las Vegas – we can match any profile brought to us! We grind custom profiles up to 9” with our knife grinding equipment. On-site in our showroom and mill we have 4,000 moulding profile knives that you can choose from.

Our state-of-the-art equipment including an upgraded knife grinder, gang rip, and moulder allows us to run standard profiles with a 3–5-day turnaround. If requesting a custom profile, turnaround is 5-7 days. We manufacture moulding from any hardwood or softwood you need, subject to the availability of raw lumber.

Types of Interior Trim

In general, moulding throughout a home or building should match. Moulding generally describes the covering of gaps between the wall and doors, windows, ceilings, and floors. Let’s go over the most common types of moulding.

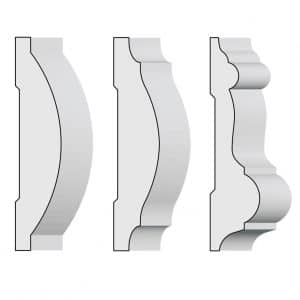

Base moulding (baseboards) runs along the floor covering the joint where the bottom of the wall and the floor meet. Base moulding throughout the home ties all the rooms together. Case moulding (trim) borders the outside of doors and windows covering the gap between the wall, acting as picture frames to the openings of the room/building. Crown moulding (cornice) caps the top of the wall where it meets the ceiling, visually elevating the ceiling height.

Types of Decorative Moulding

There are multiple types of decorative moulding that act as accents giving a personal touch and design to the home/building. The major types that we typically manufacture are for the corners, stairs, and walls.

Outside corner moulding (corner trim) encases the protruding edge of the wall for protection or to hide the seam between walls. Chair rail moulding normally sits below the windowsill, no taller than a third of the length of the wall adding dimension to an otherwise flat wall. The chair rail also earned its name by protecting dining room walls from being bruised by chairs.

To create wainscoting on the bottom half of the wall panel moulding is often paired with a chair rail. It is trim combined with raised wall panels enhancing the crown and base moulding. Plant on moulding (applied moulding) is general-purpose profiles or decorative details that can be placed on top of other elements, wherever it looks good.

Types of Moulding Joints

To connect the wood mouldings there are two major types of moulding joints used. Tongue and groove (T&G) involve milling the moulding in which the tongue of one piece fits together with the groove of another piece, interlocking. T&G is a long-lasting method for keeping the pieces together, it tends to lay flatter and allows the molding to be applied horizontally or vertically.

Shiplap involves milling the top and bottom of each piece of moulding to form a rabbet joint simply sitting evenly on top of one another. Due to its low cost and appeal to many homeowners, shiplap can be beneficial.

Woodstock Architectural Products can produce any mouldings of your dreams. We are your one-stop-shop when it comes to mouldings, book an appointment to get your order started today!